As technology advances, the demand for high-strength, reliable, and lightweight materials is skyrocketing. In response, metals have been tested, refined, and redesigned to meet these growing needs. One such metal that has risen to prominence is 7075 T6 aluminum plate. This unique alloy is the prime choice for a wide range of industries due to its exceptional properties. But what exactly makes it so extraordinary?

In this article, we’ll take a closer look at this widely sought-after material. We’ll discuss why the 7075 T6 aluminum plate is so highly regarded and delve into its main applications and benefits. Additionally, we’ll share some pointers for effectively handling and processing this alloy. To wrap things up, we’ll address some frequently asked questions about the 7075 T6 aluminum plate. So, buckle up and let’s dive right in!

7075 Aluminum Sheet

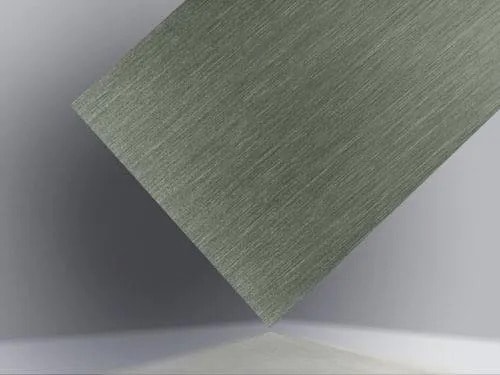

The Impressive Characteristics of 7075 T6 Aluminum Plate

The 7075 T6 aluminum plate has gained its reputation for a good reason: it boasts an outstanding set of properties that make it an optimal choice for various applications. Some of these key attributes include:

High Strength-to-Weight Ratio

This alloy has an excellent balance of strength and weight. 7075 T6 aluminum plate is much lighter than steel, yet it maintains impressive strength, making it an ideal choice for industries where weight reduction is crucial.

Remarkable Corrosion Resistance

Thanks to the presence of zinc as the primary alloying element, 7075 T6 aluminum plates are known for their exceptional resistance to corrosion. Consequently, this material remains durable and reliable in various environments, including those with high moisture levels.

Outstanding Machinability

Working with 7075 T6 aluminum plate is a breeze, as it can be easily machined and fabricated to suit specific applications. This ease of processing makes it an attractive option for industries that require custom components, such as aerospace and automotive.

Impressive Fatigue Resistance

One of the significant advantages of 7075 T6 aluminum plate is its resistance to fatigue. This means that it can withstand repeated stress and strain without significant degradation, making it an excellent choice for applications that demand endurance.

Top Applications for 7075 T6 Aluminum Plate

Due to its remarkable properties, 7075 aluminum plate has become a preferred material in various industries. Here are some of the sectors that heavily employ this alloy:

-

Aerospace: Aerospace components rely on lightweight, yet strong materials that can survive extreme conditions. Thanks to its high strength-to-weight ratio and fatigue resistance, 7075 T6 aluminum plate has become a go-to choice in this field.

-

Automotive: Similar to aerospace, automotive applications also benefit from the impressive strength-to-weight ratio of 7075 T6 aluminum plate. Its corrosion resistance and machinability make it ideal for manufacturing various parts, such as suspension components and gears.

-

Sporting Equipment: The lightweight and durable nature of 7075 T6 aluminum plate make it an excellent selection for sports equipment, including bicycle frames and golf club shafts, ensuring optimal performance and longevity.

-

Military: The military has long recognized the advantages of 7075 T6 aluminum plate, using it for the production of firearms, missile components, and more. Its durability, reliability, and lightweight characteristics make it highly regarded for these critical applications.

Working with 7075 T6 Aluminum Plate: Tips and Tricks

Despite its outstanding machinability, handling and processing 7075 T6 aluminum plate require a certain level of expertise. Here are some tips to help you work with this excellent material effectively:

-

Choose the right cutting tools: To achieve precise cuts and extend tool life, use sharp, carbide-tipped cutting tools designed specifically for aluminum alloys.

-

Ensure proper cooling: During machining processes, be sure to provide adequate coolant or lubricant to prevent the material from overheating.

-

Keep in mind material thickness: When bending 7075 T6 aluminum plate, always consider the material’s thickness. Thinner plates can be more susceptible to cracking in the bending process.

-

Implement heat treatment: Often, heat treatment is necessary to develop the desired properties of 7075 T6 aluminum plate. Consult an expert to determine the appropriate heat treatment process for your specific application.

FAQs about 7075 T6 Aluminum Plate

Is 7075 T6 aluminum plate weldable?

Technically, welding 7075 T6 aluminum plate is possible. However, due to its high zinc content, welding can lead to a significant reduction in the material’s strength. Therefore, it’s generally advised to avoid welding 7075 T6 aluminum plate and instead rely on other joining methods, such as riveting or bolting.

How does 7075 T6 aluminum plate compare to other aluminum alloys?

7075 T6 aluminum plate is famed for its superior strength when compared to other aluminum alloys. While it may be slightly less versatile in terms of workability, this alloy’s exceptional properties make it well-suited for applications where strength and durability are paramount.

What does “T6” indicate in 7075 T6 aluminum plate?

The “T6” in 7075 T6 aluminum plate signifies its temper or heat treatment condition. In this case, T6 indicates that the material has undergone solution heat treatment followed by artificial aging, resulting in maximum strength and hardness.

Conclusion

In conclusion, 7075 T6 aluminum plate is an excellent material choice for industries that value strength, corrosion resistance, and fatigue resistance in a lightweight package. This alloy is incredibly versatile, finding practical use in aerospace, automotive, sporting goods, and military applications. By following the tips and tricks provided, handling and processing 7075 T6 aluminum plate should be a simple and efficient process, enabling you to reap the benefits of this remarkable material.