7075 Aluminum Sheet

| Alloy | |

|---|---|

| Temper | O-H112, T3-T8, T351-T851 |

| Surface Treatment | Anodized, Coated, Embossed, Mill Finished, Polished mirror, Powder Coated, Printed |

| Thickness | 0.1mm-350mm |

| Width | 100mm-2200mm |

| Sample | Freely |

| Standard | ASTMB209, EN573-1S, etc |

| Certificate | MTC, ISO9001,SGS, ROHS,DNV,TUV,ISO14001,ABS,CCS,CE |

| Delivery time | Future Goods: 15-30 days, Ready stock: 7-10 days |

7075 Aluminum Sheet Product Introduction

7075 aluminum sheet belongs to Al-Zn-Mg-Cu super duralumin, which is a cold-treated forging alloy with high strength and hardness, far better than soft steel. At present, 7075 aluminum sheet is the preferred metal material under the requirement of lightweight conditions with lower density and higher hardness. It is one of the most potential alloys for commercial use. And It is widely used in the manufacturing of shoe mold, high-hardness mold, high-end mobile phone shell, thick plate, heavy forging and golf components, precision parts and aircraft.

All our products are manufactured with advanced equipment and strict QC procedures in order to insures every product's high quality. With 23 years of experience in the source manufacturers, we can supply competitive prices. Sample can be provided as per your requirements for free.

We also offer 7005 aluminum sheet,7050 aluminum sheet,7A04 aluminum sheet, and other types for you to choose from.

7075 Aluminum Sheet

7075 Aluminum Sheet Advantages

1. High Intensity. 7075 aluminum sheet is stronger than mild steel. After solution treatment, the plasticity is good, with high strength below 150℃ and excellent low temperature strength.

2. Strong Stress Corrosion. The stress corrosion performance of 7075 aluminum shee is better than that of 7A04, especially in the temper of 7075-t651.

3. Good Heat Treatment Strengthenin Effect. Zn is the main alloy element in 7075 aluminum sheet. Mg is added to the alloy containing 3%-7.5% Zn, so that the heat treatment strengthening effect of 7075 aluminum alloy is far better than that of Al-Zn binary alloy.

4. Other features. The plasticity under annealing and hardening conditions is slightly lower than 2A12 in the same state, but slightly better than 7A04, etc.

Product Specifications

Yongsheng Aluminum Sheet Basic Parameters

|

Product Name

|

Aluminum Sheets

|

|||

|

Alloy/Grade

|

1000 Series, 2000 Series, 3000 Series, 5000 Series, 6000 Series, 7000 Series,8000 Series

|

|||

|

Temper

|

O-H112,T3-T8,T351-T851

|

|||

|

Thickness

|

0.006mm-6.5 mm(According to customer requirements)

|

|||

|

Width

|

3 mm-2600 mm(According to customer requirements)

|

|||

|

Application

|

roofing, ceiling, cladding, gutter, facade wall, etc.

|

|||

|

Surface treatment

|

Mill Finish、Coated、Powder Coated、Anodized、Polished mirror、Embossed、Etc.

|

|||

|

Tolerances

|

As per your requirements

|

|||

|

Delivery time

|

7-30 days after order confirmation

|

|||

|

MOQ

|

1 ton each size or less if we have the same specification in stock.

|

|||

|

Loading Port

|

Qingdao Port, Tianjin Port, Shanghai port.

|

|||

|

Price terms

|

FOB, CIF, CFR, CNF, Etc.

|

|||

|

Payment terms

|

L/C, D/A, D/P, T/T, West Union, Money Gram, Etc.

|

|||

|

Package

|

Seaworthy Wooden pallet, Wooden case, Aluminum plate case

|

|||

|

Our Service

|

We can provide you with free samples and various custom services.

|

|||

7075 Aluminum Sheet Chemical Composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 0.12 | 0.15 | 2.0-2.6 | 0.1 | 1.9-2.6 | 0.04 | 5.7-6.7 | 0.06 | Remainder |

Aluminum Sheet Series Introduction

| 1000 Series | Industrial Pure Aluminum(1050,1060 ,1070, 1100) |

| 3000 Series | Aluminum-manganese alloys(3A21, 3003, 3103, 3004, 3005, 3105) |

| 5000 Series | Al-Mg alloys(5052, 5083, 5754, 5005, 5086,5182) |

| 6000 Series | Aluminum Magnesium Silicon Alloys(6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02) |

| 7000 Series | Aluminum, Zinc, Magnesium and Copper Alloys(7075, 7A04, 7A09, 7A52, 7A05) |

7075 Aluminum Sheet Mechanical Properties

- Tensile strength σb (MPa): ≥560

- Elongation stress σp0.2 (MPa): ≥495

- Elongation δ5 (%): ≥6

Packaging of Aluminum Sheet

Yongsheng aluminum sheet is placed on a wooden pallet or wooden box, wrapped perfectly with waterproof craft paper, and then fixed with a narrow strip of iron.

Usually, we have six layers of packing: put on wooden supports and put desiccant, wrap moisture-proof film, wrap the plastic film, wrap the moisture-proof cotton, wrap the plastic moisture-proof film again and pack it with cardboard.

aluminum sheet packing

7075 Aluminum Sheet Application

For the production of aircraft structures and other high-stress, corrosion-resistant structures, such as upper and lower wing panels, trusses, and spacers. Furthermore, 7075 aluminum sheet is used in the manufacture of high-end mobile phone casings, precision components, golf components, and other products.

7075 Aluminum Sheet Plate Physical Properties

- Tensile strength: 524Mpa

- 0.2% yield strength: 455Mpa

- Elastic modulus E: 71GPa

- Hardness: 150HB

- Density: 2.81g/cm^3 [1]

- Poisson's ratio: 0.33

Aluminum Sheet Production Process

Smelting —— Ingot casting —— Pre-rolling preparation —— Flat roll rolling —— Heat treatment ——Finishing——Final Inspection——Packing——Delivery

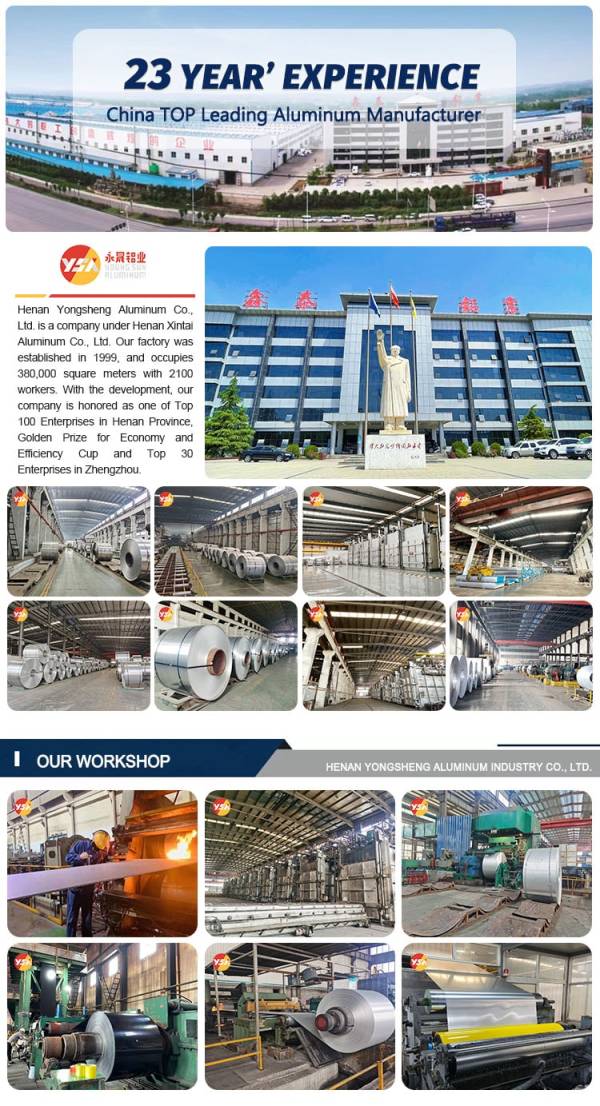

Henan Yongsheng Aluminum Co., Ltd. was established in 1999 and occupies 380,000 square meters with 2100 workers. With the development, our company has been honored as one of Top 100 Enterprises in Henan Province, Golden Prize for Economy and Efficiency Cup and Top 30 Enterprises in Zhengzhou.

We are a Chinese Leading aluminum sheet manufacturer, our main products are as following: Aluminum Sheet/Plate/Coil/Strip/Circle/Foil, Color-coated Aluminum, Aluminum Checker Plate, Mirror Aluminum Sheet and so on. Our capacity is 300,000 MT per year, among which, 35% are exported overseas. At the same time, we supply much famous aluminum companies in China.

Welcome to visit our factory and look forward to establishing a long-term business relationship with you!!!