3003 Aluminum Sheet

| Alloy | |

|---|---|

| Temper | O-H112, T3-T8, T351-T851 |

| Surface Treatment | Anodized, Coated, Embossed, Mill Finished, Polished mirror, Powder Coated, Printed |

| Thickness | 0.1mm-350mm |

| Width | 100mm-2200mm |

| Length | Any length, according to the transportation, usually less than 12m |

| Standard | ASTMB209, EN573-1S, etc |

| Delivery time | Future Goods: 15-30 days, Ready stock: 7-10 days |

3003 Aluminum Sheet Product Introduction

3003 aluminum sheet is a typical Al-Mn antirust alloy. 3003 aluminum sheet has excellent weldability, formability and other advantages, and has become a popular and economical choice for "home appliance components". 3003 aluminum sheet is widely used in power battery shell materials, ships, vehicle materials, automobile plate welding parts, pressure vessels, refrigeration devices, air conditioning pipes, cans, TV towers, drilling equipment, mechanical parts, transportation equipment, etc.

Yongsheng Aluminum is a 3003 aluminum sheet manufacturer with a production thickness of 1-600mm. Our factory can customize production and sell it all over the world. Yongsheng 3003 aluminum has excellent performance and provides original factory warranty, so we can rest assured to buy and use!

Yongsheng 3003 aluminum sheet price is reasonable and very competitive. We also offer 3004 aluminum sheet,3104 aluminum sheet,3105 aluminum sheet, and other types for you to choose.

3003 Aluminum Sheet

3003 Aluminum Sheet Advantages

1. Corrosion Resistance. 3003 aluminum sheet has good corrosion resistance, which is close to the corrosion resistance of pure industrial aluminum. It can effectively resist the corrosion of atmosphere, freshwater, seawater, food, organic acids, gasoline, neutral inorganic salt solution, and dilute acids.

2. High Plasticity. In the annealed temper, the plasticity of 3003 aluminum sheet is very high. In the case of semi-cold work hardening, its plasticity is still good, and its plasticity is low when it is cold worked. Good weldability and poor machinability.

3. Weak Resistance to Peeling Corrosion. In the cold deformed state, 3003 aluminum sheet has a tendency to peel and corrode. The larger the deformation is, the more severe the peeling is. Because the color is not uniform after anodizing, anodizing is generally not performed.

Product Specifications

Yongsheng Aluminum Sheet Basic Parameters

|

Product Name

|

Aluminum Sheets

|

|||

|

Alloy/Grade

|

1000 Series, 2000 Series, 3000 Series, 5000 Series, 6000 Series, 7000 Series,8000 Series

|

|||

|

Temper

|

O-H112,T3-T8,T351-T851

|

|||

|

Thickness

|

0.006mm-6.5 mm(According to customer requirements)

|

|||

|

Width

|

3 mm-2600 mm(According to customer requirements)

|

|||

|

Application

|

roofing, ceiling, cladding, gutter, facade wall, etc.

|

|||

|

Surface treatment

|

Mill Finish、Coated、Powder Coated、Anodized、Polished mirror、Embossed、Etc.

|

|||

|

Tolerances

|

As per your requirements

|

|||

|

Delivery time

|

7-30 days after order confirmation

|

|||

|

MOQ

|

1 ton each size or less if we have the same specification in stock.

|

|||

|

Loading Port

|

Qingdao Port, Tianjin Port, Shanghai port.

|

|||

|

Price terms

|

FOB, CIF, CFR, CNF, Etc.

|

|||

|

Payment terms

|

L/C, D/A, D/P, T/T, West Union, Money Gram, Etc.

|

|||

|

Package

|

Seaworthy Wooden pallet, Wooden case, Aluminum plate case

|

|||

|

Our Service

|

We can provide you with free samples and various custom services.

|

|||

3003 Aluminum Sheet Physical Properties

| Temper | Thickness (mm) | Tensile Strength (Mpa) | Yield Strength (Mpa) | elongation(%) | hardness(HV) |

| 0 | >0.2-0.5 | 95-140 | ≥35 | ≥15 | 30-40 |

| >0.5-1.0 | ≥30 | ||||

| >1.0-4.0 | ≥35 | ||||

| H22 | >0.2-0.5 | 120-160 | ≥90 | ≥12 | 39-53 |

| >0.5-1.0 | ≥15 | ||||

| >1.0-4.0 | ≥18 | ||||

| H24 | >0.2-0.5 | 145-195 | ≥125 | ≥6 | 42-59 |

| >0.5-1.0 | ≥8 | ||||

| >1.0-4.0 | ≥10 | ||||

| H26 | >0.2-0.5 | 170-210 | ≥150 | ≥2 | 55-65 |

| >0.5-1.0 | ≥4 | ||||

| >1.0-4.0 | ≥6 | ||||

| H18 | >0.2-0.5 | ≥190 | ≥170 | ≥2 | 60-85 |

| >0.5-1.0 | ≥3 | ||||

| >1.0-4.0 | ≥4 |

3003 Aluminum Sheet Chemical Composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | _ | _ | 0.1 | _ | Remainder |

3003 Aluminum Sheet VS 1100 Aluminum Sheet

Approx. 20% higher strength than the 1100 series, but retaining an excellent workability rating. May show some slight discoloration when anodized, but reacts well to mechanical and organic finishings. 3003 is easily welded and brazed, but solder is limited to the torch method. Like 1100, tends to be "gummy" when machined. Non-heat treatable. Typical applications include food and chemical equipment, appliance components, truck and trailer roofing, heat exchangers, and lawn furniture components.

3003 Aluminum Sheet Packing

Yongsheng aluminum sheet is placed on a wooden pallet or wooden box, wrapped perfectly with waterproof craft paper, and then fixed with a narrow strip of iron.

Usually, we have six layers of packing: put on wooden supports and put desiccant, wrap moisture proof film, wrap the plastic film, wrap the moisture-proof cotton, wrap the plastic moisture proof film again and pack it with cardboard

aluminum sheet packing process

3003-H14 Aluminum Plate

3003-H14 Aluminum Plate - (ASTM B209, QQ-A-250/2) Excellent weldability, formability, with good corrosion resistance make 3003 Aluminum Plate a popular and economical choice. 3003 Aluminum Plate has a smooth, shiny finish and is popular for many cosmetic and industrial applications, including: Decorative trim, fuel tanks, food & chemical handling, trailer siding & roofing, etc.

3003-h14 aluminum sheet

Product Applications

Typical uses of 3003 aluminum sheet: heat sinks, radiators, power battery enclosures, automotive heat shields, fuel tanks, water tanks, automotive skid plates, battery explosion-proof valves, battery covers, automotive interiors, signs, cans, medical equipment, etc.

Typical use of Ultra-wide3003 aluminum sheet: bus skins, silos, antenna pan materials, wide curtain wall panels, wide roof panels, etc.

Use of 3003 aluminum sheet foil coils: honeycomb core aluminum foil, electronic foil, honeycomb material, lunch box material, container foil, etc.

3003 Aluminum Sheet Application

3000 Series Aluminum Sheet

The 3000 series aluminum plate is mainly 3003 3005 3A21. It can also be called anti-rust aluminum plate. The production process of the 3000 series aluminum plate in our factory is very good. The 3000 series aluminum plate is mainly composed of manganese. The content is between 1.0-1.5. It is a series with better anti-rust function. Routinely used in humid environments such as air conditioners, refrigerators, and undercars, the price is higher than the 1000 series, and it is a more commonly used alloy series.

The following 3 series aluminum sheets are on sale:

3003 Aluminum Sheet

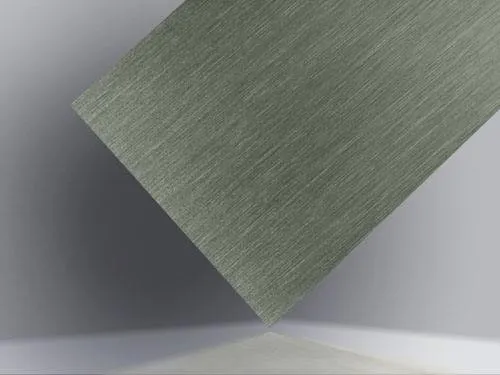

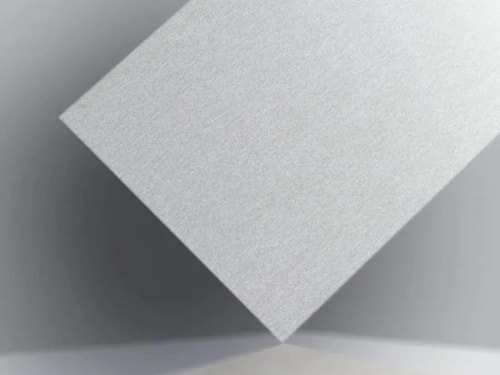

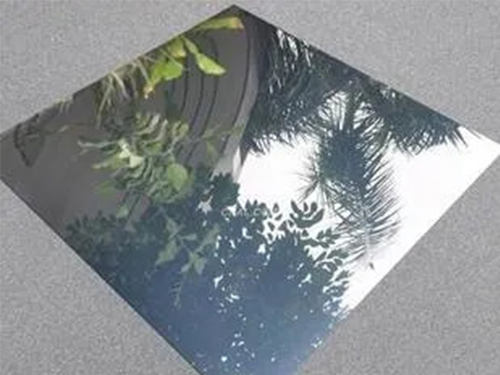

Aluminum Sheet Surface Finish

Anodized, mirror, embossed stucco, etc

Color coated: natural, black, white, blue, red, orange, rose gold, green, golden, etc

Aluminum Sheet Production Process

Smelting —— Ingot casting —— Pre-rolling preparation —— Flat roll rolling —— Heat treatment ——Finishing——Final Inspection——Packing——Delivery

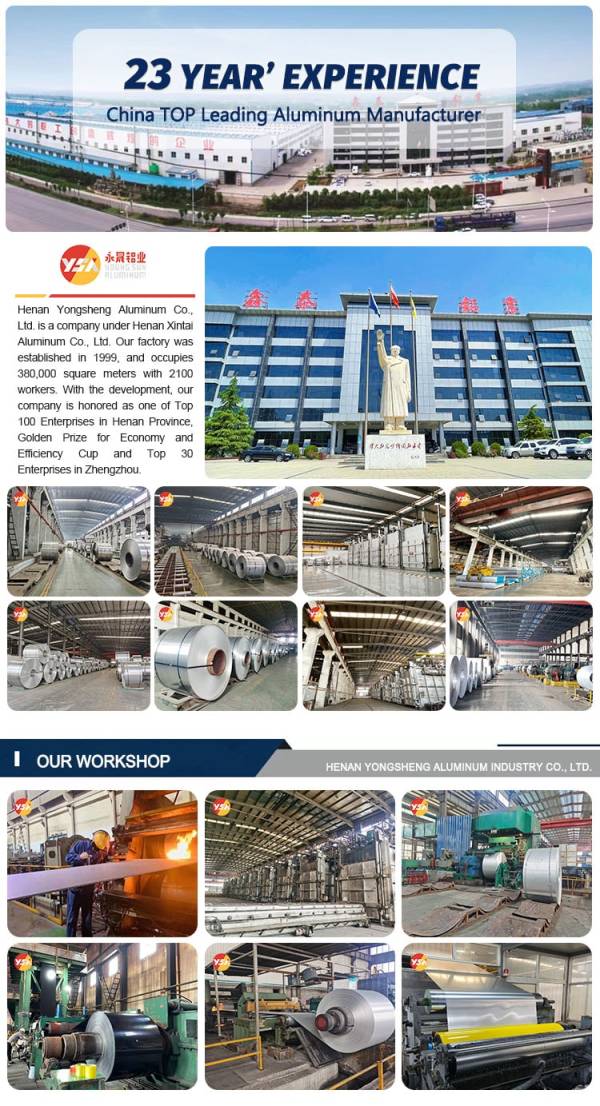

Henan Yongsheng Aluminum Co., Ltd. was established in 1999 and occupies 380,000 square meters with 2100 workers. With the development, our company has been honored as one of Top 100 Enterprises in Henan Province, Golden Prize for Economy and Efficiency Cup and Top 30 Enterprises in Zhengzhou.

We are a Chinese Leading aluminum sheet manufacturer, our main products are as following: Aluminum Sheet/Plate/Coil/Strip/Circle/Foil, Color-coated Aluminum, Aluminum Checker Plate, Mirror Aluminum Sheet and so on. Our capacity is 300,000 MT per year, among which, 35% are exported overseas. At the same time, we supply much famous aluminum companies in China.

Welcome to visit our factory and look forward to establishing a long-term business relationship with you!!!