Have you ever wondered what lies behind the scenes of the sleek and shiny aluminum products we use daily? The answer – mill finish aluminum sheets! These humble yet versatile sheets form the backbone of innumerable applications in various industries, thanks to their unique properties.

Let’s embark on a fascinating journey to explore the intriguing world of mill finish aluminum sheets from production to practical applications.

Laying the Foundation: The Manufacturing Process Unraveled

Understanding the vital role mill finish aluminum sheets play in numerous industries requires a sneak peek into their production process. Let’s take a quick look at the steps involved:

1. Raw Material: Bauxite Mining

All aluminum products have their roots in bauxite, a reddish-brown rock abundant in the Earth’s crust. Bauxite contains approximately 30-50% of aluminum hydroxide, the key component for the extraction of aluminum.

2. The Alumina Connection: From Bauxite to Alumina

Through a three-step process called the Bayer Process, aluminum hydroxide is extracted from bauxite and transformed into alumina (aluminum oxide). The key steps are:

- Crushing and grinding bauxite

- Heating the mixture and dissolving it in sodium hydroxide

- Precipitating and collecting the alumina

3. Electrolytic Revelation: Alumina to Aluminum

The bauxite journey doesn’t end here! A smelting process called electrolysis further refines the alumina to aluminum. In a reduction cell, the alumina melts and breaks down into aluminum and oxygen during an electrochemical process.

4. Rolling in Progress: Creating Mill Finish Aluminum Sheets

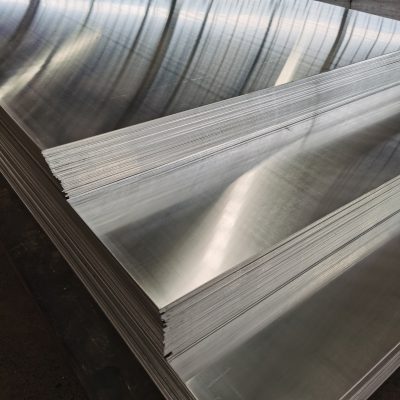

Now that the aluminum is extracted, it’s time to create the sheets! Aluminum slabs are heated and rolled into a continuous length, which is then cooled and recoiled into a coil of aluminum sheet material. Embrace yourselves! It’s finally time to meet the star of the show – the mill finish aluminum sheet.

Mill Finish – The Natural Vibe of Aluminum Sheets

As the name suggests, mill finish refers to the natural finish that the aluminum sheet exhibits after passing through the rolling mill. In other words, there is no additional treatment required after production. The visually appealing matte texture, with its inherent brushed-like appearance, is rust-resistant and easy to maintain.

But don’t jump to conclusions yet! Mill finish aluminum sheets are also a blank canvas waiting for customization–from anodizing to painting–the possibilities are endless.

The Pillars of Strength: Properties and Classifications

Mill finish aluminum sheets boast several properties that make them indispensable in multiple industries. Here’s a quick rundown of their key traits:

- Lightweight

- Durable

- Corrosion and rust-resistant

- Excellent thermal and electrical conductivity

- Highly reflective

- Malleable and versatile

Classifying the Goods: Aluminum Sheet Series

There are several classifications or series of aluminum sheets based on their alloy composition, each boasting different properties and applications. Some popular series are:

- 1xxx Series – Pure aluminum

- 3xxx Series – Known for corrosion resistance and moderate strength

- 5xxx Series – Superior corrosion resistance and welding compatibility

- 6xxx Series – Ideal for structural applications due to high strength and corrosion resistance

Ingenious Applications: Where Mill Finish Aluminum Sheets Reign Supreme

Mill finish aluminum sheets are the unsung heroes, quietly shining in various industries. Let’s get up close and personal with their myriad of applications:

- Automobile components

- Aerospace components

- Heat exchanger components

- Building and construction materials

- Packaging materials, such as foils and cans

- Electrical and electronic products

- Home appliances

Navigating the Buying Maze: Frequently Asked Questions (FAQs)

Q1: How do I choose the right mill finish aluminum sheet for my project? A1: Consider factors such as thickness, alloy composition, tensile strength, and the specific application to select the ideal sheet.

Q2: Can mill finish aluminum sheets be customized? A2: Yes, these sheets can be anodized, painted, or coated to achieve the desired finish, color, or increase corrosion resistance.

Q3: Why should I opt for a mill finish aluminum sheet instead of a pre-treated aluminum sheet? A3: Choosing mill finish aluminum sheets offers flexibility in customization for specific projects and may also be a cost-effective option due to their raw, untreated state.

Conclusion: The Unparalleled Versatility of Mill Finish Aluminum Sheets

Mill finish aluminum sheets truly are the unsung heroes in countless applications across the globe. Their natural, untreated state provides a fresh canvas for customization, while their unique properties make them indispensable across various industries. Next time you encounter a sleek and shiny aluminum product, remember the mighty mill finish aluminum sheet – the hidden gem that started it all.