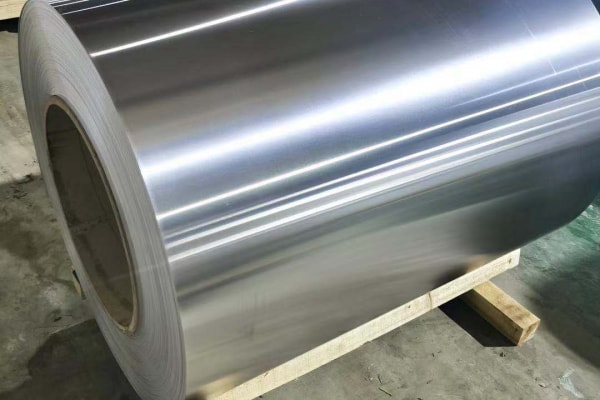

Industrial aluminum production is the process of creating aluminum products for use in various industries. This process involves extracting aluminum from bauxite ore, refining and smelting it, and then shaping it into different forms. Aluminum sheet rolls are one of the products resulting from this process that has a wide range of uses in various industries. In this article, we will explore the manufacturing process of aluminum sheet rolls, their industrial applications, and the benefits of using them.

Aluminum Sheet Roll Manufacturing

The manufacturing of aluminum sheet rolls involves a series of processes that transform raw aluminum into a thin and flat sheet. Firstly, the extracted aluminum is refined and smelted, followed by the casting of the liquid metal into ingots. These ingots are then heated and rolled into sheets of varying thicknesses, depending on the intended use. The sheets are then further processed through cutting, smoothing, and finishing to create the final aluminum sheet rolls.

Several factors affect the manufacturing process of aluminum sheet rolls, including the specific alloy used, the degree of stretching and rolling, and the desired finish. Factors that can impact the final product include temperature, humidity, and pressure. The quality of the raw materials and the manufacturing process are crucial for producing high-quality aluminum sheet rolls that meet industry standards.

Advantages of Using Aluminum Sheet Rolls

One of the main benefits of using aluminum sheet rolls is their high strength-to-weight ratio. This makes them suitable for use in various applications where strength and durability are necessary, such as the transportation, construction, and renewable energy industries. Additionally, aluminum sheet rolls are resistant to corrosion, making them ideal for outdoor use in a range of environments.

Industrial Applications of Aluminum Sheet Rolls

Aluminum sheet rolls have a broad range of industrial applications in various industries due to their durability, strength, and versatility. Some of the most common industries that utilize aluminum sheet rolls include:

Transportation Industry

Aerospace Industry

Aluminum sheet rolls are commonly used in the aerospace industry, where lightweight materials are necessary to reduce fuel consumption and increase speed. Airplanes and spacecraft require high-strength, lightweight materials for their structural components, and aluminum sheet rolls provide an excellent solution.

Automotive Industry

The automotive industry has also incorporated aluminum sheet rolls in their product designs. These sheets are useful in creating lightweight automotive bodies, which results in better performance, lower fuel consumption, and more efficient vehicles.

Marine Industry

The marine industry uses aluminum sheet rolls in the manufacturing of boats and ships. Aluminum sheet rolls are useful for constructing hulls, decks, and superstructures in boats and ships, as these components should be lightweight and resistant to corrosion.

Building and Construction Industry

Aluminum sheet rolls are widely used by the building and construction industry, where durability, strength, and resistance to corrosion are necessary. These sheet rolls are useful in creating roofing, wall cladding, and window frames.

Renewable Energy Industry

The renewable energy industry uses aluminum sheet rolls to create wind turbines, solar panels, and other renewable energy systems. Aluminum sheets are useful in constructing these structures as they are strong, lightweight, and resistant to corrosion.

Choosing the Right Aluminum Sheet Roll

There are several factors to consider when choosing the right aluminum sheet roll for a particular industry. These include:

Thickness and Strength

The thickness and strength of the sheet should be appropriate for the intended use. Industrial applications in different industries have specific requirements, and the sheet roll’s thickness and strength should meet these requirements.

Alloy Type

The specific alloy type of the aluminum sheet roll also plays a critical role in determining its strength and durability. Alloy types vary in strength, corrosion resistance, and other features, and each type is suitable for specific applications.

Surface Finish

The surface finish of the sheet roll is another crucial factor to consider when selecting a roll. Depending on the intended use, a sheet roll may require a specific surface finish, such as matte, polished, or brushed.

Compliance with Industry Standards

Finally, it is essential to choose a sheet roll that meets industry standards and regulations. Compliance with industry standards ensures the quality and durability of the product.

Benefits of Using Industrial Aluminum Sheet Rolls

Using industrial aluminum sheet rolls has many benefits over other materials. Some of these benefits include:

Durability and Longevity

Aluminum sheet rolls can withstand extreme temperatures, corrosion, and wear, making them a durable and long-lasting material for various industrial applications.

Cost-Effectiveness

Aluminum sheet rolls are cost-effective in the long run. Although they may have a higher upfront cost than other materials, their durability and longevity make them cost-efficient over time.

Versatility

Aluminum sheet rolls are versatile and adaptable to different industrial applications. They can be manufactured in different thicknesses and sizes, making them suitable for different markets and industries.

Sustainability

Aluminum sheet rolls are a more sustainable option than other materials. Aluminum is a recyclable material, which means that used sheets can be recycled and used in future products. This contributes to sustainability and makes aluminum sheet rolls a more environmentally friendly option.

Conclusion

Aluminum sheet rolls have become a critical material in various industries, thanks to their strength, durability, and versatility. Choosing the right sheet roll for a specific industrial application involves considering factors, such as thickness, alloy type, and surface finish. By partnering with industry-leading experts in industrial aluminum production, businesses can access high-quality aluminum sheet rolls that meet their requirements and comply with industry standards.

FAQs

-

What is industrial aluminum production, and why is it important? Industrial aluminum production is the process of creating aluminum products for use in various industries. Aluminum is a lightweight, durable, and versatile material that has many applications in different industries, from transportation to construction and renewable energy. Industrial aluminum production is essential because it enables businesses to access high-quality aluminum products that meet industry standards and comply with regulations.

-

What factors affect the manufacturing process of aluminum sheet rolls? Several factors affect the manufacturing process of aluminum sheet rolls, including temperature, humidity, and pressure. The specific alloy used, the degree of stretching and rolling, and the desired finish also affect the manufacturing process, resulting in different types of sheet rolls.

-

What are the industrial applications of aluminum sheet rolls? Aluminum sheet rolls have a wide range of industrial applications in various industries, including the transportation, construction, and renewable energy industries. They are commonly used in the aerospace, automotive, and marine industries, as well as in creating renewable energy systems.

-

How do you choose the right aluminum sheet roll for a particular industry? Choosing the right aluminum sheet roll requires considering factors such as thickness and strength, alloy type, surface finish, and compliance with industry standards. These factors help determine the sheet roll’s suitability for a specific industrial application.

-

What are the benefits of using industrial aluminum sheet rolls over other materials? The benefits of using industrial aluminum sheet rolls include durability and longevity, cost-effectiveness, versatility, and sustainability. Aluminum sheet rolls are a durable, cost-efficient, and sustainable material that can withstand extreme temperatures and resist corrosion, making them suitable for various industrial applications.