5052 Aluminum Sheet

| Temper | O-H112, T3-T8, T351-T851 |

|---|---|

| MOQ | We can accept 500kg each size or less if we have the same specification in stock. |

| Delivery time | Future Goods: 15-30 days, Ready stock: 7-10 days |

| Certificate | MTC, ISO9001,SGS, ROHS,DNV,TUV,ISO14001,ABS,CCS,CE |

| Length | Any length, according to the transportation, usually less than 12m |

| Price terms | FOB, CIF, CFR, CNF, etc. |

| Quality Control | Mill Test Certification is supplied with shipment,Third Part Inspection is acceptable. |

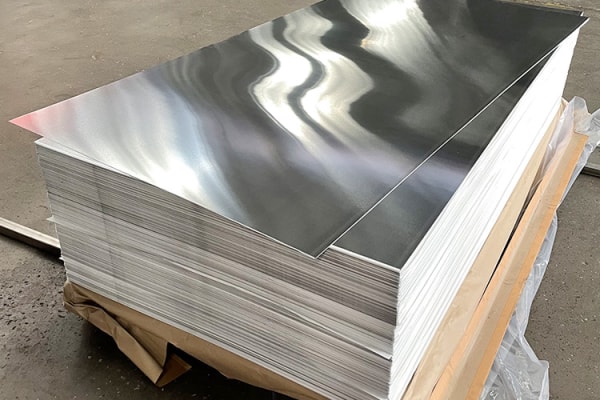

5052 Aluminum Sheet Product Introduction

As a reliable aluminum supplier, our factory strictly controls the production process to ensure the high quality of 5052 aluminum sheet. With a high content of Mg, this rust-proof alloy has been widely used in various fields, such as 3C products, car doors, and architectural curtain wall panels. Its excellent corrosion resistance, weldability, and formability make it an ideal choice for manufacturers.

5052 aluminum sheet is one of the most popular and widely used aluminum alloy products of Yongsheng Aluminum Factory. The 5052 aluminum plate we produce has the characteristics of high product market recognition, skilled processing technology and stable product performance.

We also offer 5083 aluminum sheet,5754 aluminum sheet,5182 aluminum sheet, and other types for you to choose from.

5052 Aluminum Sheet

5052 Aluminum Sheet Advantages

1. Good Weldability. The addition of Cr in the 5052 aluminum sheet interacts with Mn, which can increase the strength between the base metal and the weld, thereby reducing the tendency of welding cracks and meeting various welding requirements.

2. Corrosion Resistance. Corrosion resistance is a typical characteristic of 5052 aluminum sheet. It has good corrosion resistance to the atmosphere, gasoline, food, organic acids, neutral inorganic salt solution, etc., and also has good corrosion resistance in dilute acids.

3. Good Plasticity. 5052 aluminum sheet is also a non-heat-treated alloy. Its mechanical properties are improved by cold working. And the 5052 aluminum sheet has good plasticity in semi-cold work hardening and low plasticity in cold work hardening.

4. Other Characteristics. In addition, the 5052 aluminum sheet also has a strong resistance to stress corrosion cracking, and can also be polished, anodized, etc.

Product Specifications

Yongsheng Aluminum Sheet Basic Parameters

|

Product Name

|

Aluminum Sheets

|

|||

|

Alloy/Grade

|

1000 Series, 2000 Series, 3000 Series, 5000 Series, 6000 Series, 7000 Series,8000 Series

|

|||

|

Temper

|

O-H112,T3-T8,T351-T851

|

|||

|

Thickness

|

0.006mm-6.5 mm(According to customer requirements)

|

|||

|

Width

|

3 mm-2600 mm(According to customer requirements)

|

|||

|

Application

|

roofing, ceiling, cladding, gutter, facade wall, etc.

|

|||

|

Surface treatment

|

Mill Finish、Coated、Powder Coated、Anodized、Polished mirror、Embossed、Etc.

|

|||

|

Tolerances

|

As per your requirements

|

|||

|

Delivery time

|

7-30 days after order confirmation

|

|||

|

MOQ

|

1 ton each size or less if we have the same specification in stock.

|

|||

|

Loading Port

|

Qingdao Port, Tianjin Port, Shanghai port.

|

|||

|

Price terms

|

FOB, CIF, CFR, CNF, Etc.

|

|||

|

Payment terms

|

L/C, D/A, D/P, T/T, West Union, Money Gram, Etc.

|

|||

|

Package

|

Seaworthy Wooden pallet, Wooden case, Aluminum plate case

|

|||

|

Factory Service

|

We can provide you with free samples and various custom services.

|

|||

5052 Aluminum Sheet Physical Properties

| Temper | Thickness (mm) | Tensile Strength (Mpa) | Yield Strength (Mpa) | elongation(%) | hardness(HV) |

| 0 | >0.2-0.5 | 170-215 | ≥65 | ≥14 | 50-70 |

| >0.5-1.0 | ≥17 | ||||

| >1.0-4.0 | ≥20 | ||||

| H22 | >0.2-0.5 | 210-260 | ≥130 | ≥8 | 70-85 |

| >0.5-1.0 | ≥10 | ||||

| >1.0-4.0 | ≥10 | ||||

| H24 | >0.2-0.5 | 230-280 | ≥150 | ≥4 | 80-110 |

| >0.5-1.0 | ≥6 | ||||

| >1.0-4.0 | ≥6 | ||||

| H26 | >0.2-0.5 | 250-300 | ≥180 | ≥2 | 85-115 |

| >0.5-1.0 | ≥4 | ||||

| >1.0-4.0 | ≥6 | ||||

| H18 | >0.2-0.5 | ≥270 | ≥240 | ≥2 | 95-120 |

| >1.0-4.0 | ≥3 |

5052 Aluminum Sheet Chemical Composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | _ | Remainder |

5052 Aluminum Sheet Application

The main uses of 5052 aluminum sheet include: Automotive aluminum alloys, High-end curtain wall panels, 3C products, Computer brackets, High-end oxide materials, Aluminum furniture, Door panels/door handles, Cans/covers, Shutters, Decoration, Trolley cases, Signs, etc.

5052 Aluminum Alloy Thick Plate Use: Silo, Flange material, GIS shell, Yacht, Underwear mold/shoe mold, Gas cylinder, Precision machining, etc.

5052-H32 Aluminum Sheet for Automotive: Automobile engine outer board, Bus trunk board, Bus non-slip decorative board, Automobile fuel tank, etc.

5052 Aluminum Sheet Application

What Is 5052-H32 Aluminum Sheet?

First of all: 5052 represents the brand name of the product, starting with 5 represents that the modified product is an aluminum-magnesium alloy product, and then according to the chemical composition, it can be seen that the magnesium alloy content of the product is between 2.2-2.8%, and the density is 2.68. Usually, enterprises take the middle value in the process of processing, which is 2.5% of the magnesium alloy content, so this series of aluminum sheets can become almg2.5.

Secondly: H32 represents the processing state of the product. H can be understood as the state of incomplete annealing and work hardening, that is, the product has been annealed, and the hardness has been reduced to be suitable for processing. Work hardening. 32 represents that the hardness of the modified product has been stabilized at 1/4 hardness.

Hardness level: usually the last Arabic numeral after H is directly related to the hardness value, for example, the last Arabic numeral of H32 H34 H24 h18 represents the hardness. The larger the Arabic numeral in the aluminum sheet of the same brand, the higher the hardness. For example, the hardness of H34 is higher than that of H32. The softest state directly becomes 0 state, which is more suitable as a stretching material. Arabic numerals take even numbers, 2 4 6 8 industry terms become 1/4 1/2 4/3 full hard.

Based on the above, it can be concluded that the 5052-H32 aluminum sheet belongs to the aluminum-magnesium alloy with a magnesium alloy content of around 2.5%. It has been incompletely annealed and hardened after stabilization treatment, and its hardness is 1/4. Usually, this product has strong corrosion resistance. , the surface oxidation effect is good, the bending ability is good, and the 90-degree bending does not crack. It is a typical sheet metal material, suitable for chassis cabinets and other classic materials that require bending processing.

5052 Aluminum Sheet Packing

Yongsheng aluminum sheet is placed on a wooden pallet or wooden box, wrapped perfectly with waterproof craft paper, and then fixed with a narrow strip of iron.

Usually, we have six layers of packing: put on wooden supports and put desiccant, wrap moisture proof film, wrap the plastic film, wrap the moisture-proof cotton, wrap the plastic moisture proof film again and pack it with cardboard.

Customers choose us as their preferred supplier for aluminum profiles because of our commitment to quality and customer service.

aluminum sheet packing process

5052 Aluminum Sheet VS 6061 Aluminum Sheet

Different alloying elements

In terms of alloying elements, the 5052 alloying element is magnesium, and the 6061 alloying element is magnesium and silicon.

Different status

In terms of state, 5052 has three states of H112, H24, and H32, while 6061 has only two states of T6 and T651.

Different performance

From the point of view of performance, 5052 sheet has better performance, has the characteristics of fatigue resistance, corrosion resistance, good welding performance, good plasticity, and can be polished, but it also has certain shortcomings, such as: no heat treatment strengthening, low plasticity during cold work hardening , Poor machinability and so on. The 6061 aluminum sheet has the characteristics of corrosion resistance, weldability, and good oxidation effect, so it is best for you to buy according to your needs when purchasing, so that you can buy satisfactory products.

Different application

From the point of view of the scope of application, 5052 aluminum sheet is an anti-rust aluminum alloy, so it is generally used in environments with relatively high anti-rust requirements. The 6061 aluminum sheet is generally used in places with relatively high strength requirements, so from this point of view, there are still many differences between the two.

Different tensile strength

From the perspective of tensile strength, the tensile strength of 5052 is less than or equal to 225 MPa, and the elongation is greater than or equal to 10%. The tensile strength of 6061 is greater than or equal to 180MPa, the yield strength is greater than or equal to 110MPa, and the elongation is greater than or equal to 14%.

Different market prices

From the price point of view, the price of 6061 is more expensive than that of 5052 aluminum sheet, but the performance and application of the two are different, so when you choose aluminum plate, it is best to decide according to your own needs.

Yongsheng 5052 Aluminum Sheet Supplier

-

High-quality aluminum is essential for improving product quality and stability, and gaining a competitive edge in the market.

-

Our mission is to provide customers around the world with high-quality and reasonably-priced materials.

-

We use advanced equipment and cutting-edge technology to ensure the quality of our products and services.

-

As a trusted supplier of aluminum sheets, we prioritize customer satisfaction and strive to exceed expectations every time.

-

With over 23 years of experience in the industry, our factory is well-equipped to provide customized solutions to meet your specific needs.

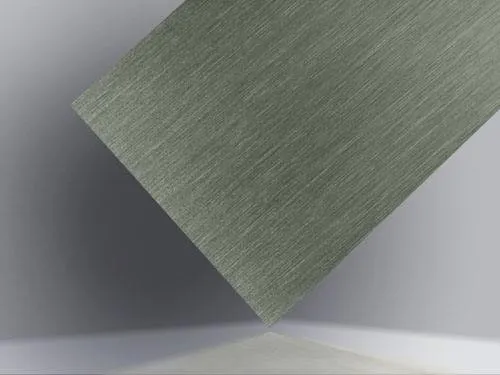

Aluminum Sheet Surface Finish

Anodized, mirror, embossed stucco, etc

Color coated: natural, black, white, blue, red, orange, rose gold, green, golden, etc

Aluminum Sheet Production Process

Smelting —— Ingot casting —— Pre-rolling preparation —— Flat roll rolling —— Heat treatment ——Finishing——Final Inspection——Packing——Delivery

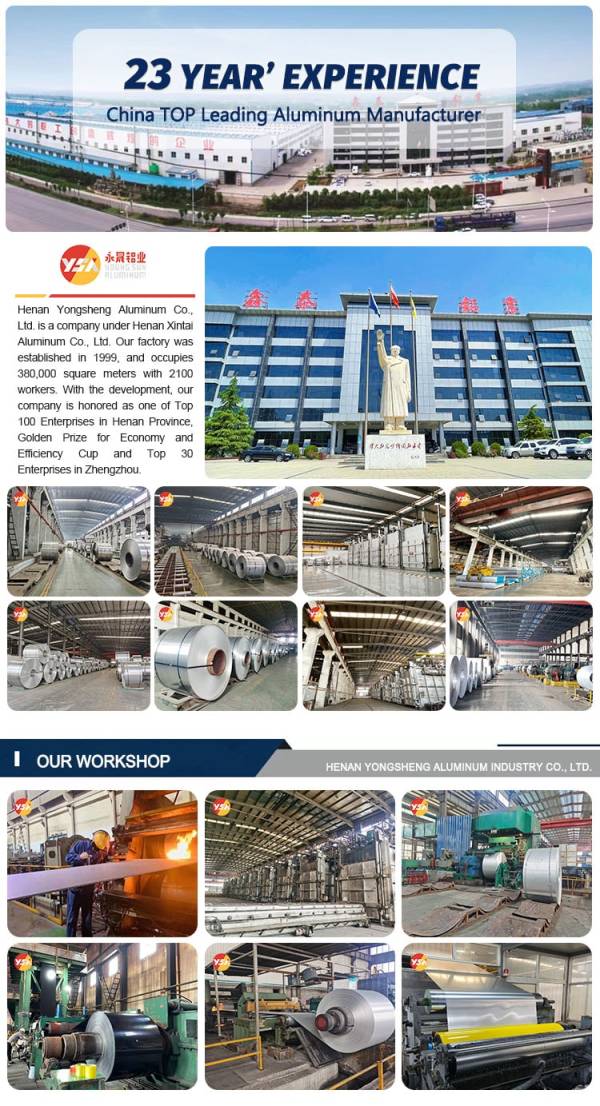

Henan Yongsheng Aluminum Co., Ltd. was established in 1999 and occupies 380,000 square meters with 2100 workers. With the development, our company has been honored as one of Top 100 Enterprises in Henan Province, Golden Prize for Economy and Efficiency Cup and Top 30 Enterprises in Zhengzhou.

We are a Chinese Leading aluminum sheet supplier, our main products are as following: Aluminum Sheet/Plate/Coil/Strip/Circle/Foil, Color-coated Aluminum, Aluminum Checker Plate, Mirror Aluminum Sheet and so on. Our capacity is 300,000 MT per year, among which, 35% are exported overseas. At the same time, we supply much famous aluminum companies in China.

Welcome to visit our factory and look forward to establishing a long-term business relationship with you!!!