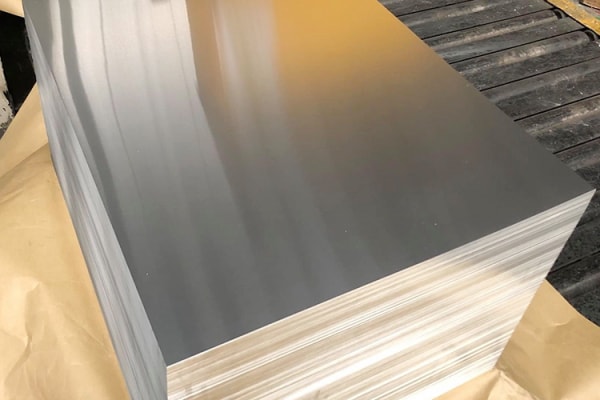

1100 Aluminum Sheet Product Introduction

1100 aluminum sheet is industrial pure aluminum, the aluminum content (mass fraction) is 99.00%, and it can not be strengthened by heat treatment. It has high corrosion resistance, electrical conductivity and thermal conductivity, low density and good plasticity.

Yongsheng is an excellent 1100 aluminum sheet supplier and we can customize processing according to customer needs. Also, We can supply competitive prices with 23 years of experience in the source manufacturers. Sample can be provided as per your requirements for free.

Yongsheng 1100 aluminum sheet price is beautiful and very competitive. We also offer 1050 aluminum sheet,1070 aluminum sheet,1100 aluminum sheet, and other types for you to choose from.

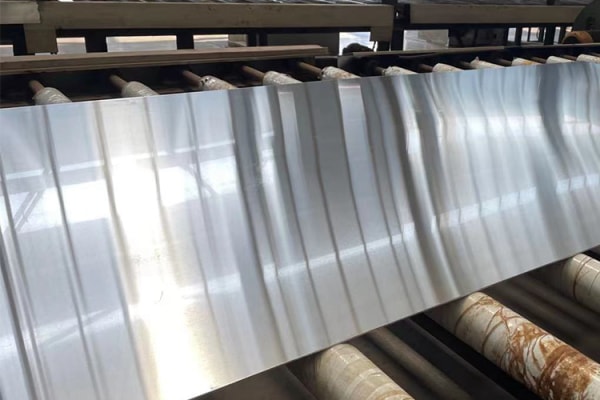

1100 Aluminum Sheet

1100 Aluminum Sheet Advantages

1. Excellent corrosion resistance. 1100 aluminum sheet has good resistance to atmospheric (including industrial atmospheric and Marine vapor) corrosion and water corrosion. In addition, it can resist the corrosion of most acids and organics.

2. Good ductility and molding. 1100 aluminum sheet can produce various aluminum materials through pressure processing, which can adapt to the larger speed of most machine tools for turning, milling, boring, planing and other mechanical processing. Moreover, the good molding of 1100 aluminum sheet enables it to be rolled into sheet and foil, or pulled into pipes and wires, etc.

3. No low-temperature brittleness.1100 aluminum sheet below 0℃, as the temperature decreases, its strength and molding will not reduce but increase.

4. The 1100 aluminum sheet strength is low, it cannot be strengthened by heat treatment, and the cutting property is poor.

Product Specifications

Yongsheng Aluminum Sheet Basic Parameters

|

Product Name

|

Aluminum Sheets

|

|||

|

Alloy/Grade

|

1000 Series, 2000 Series, 3000 Series, 5000 Series, 6000 Series, 7000 Series,8000 Series

|

|||

|

Temper

|

O-H112,T3-T8,T351-T851

|

|||

|

Thickness

|

0.006mm-6.5 mm(According to customer requirements)

|

|||

|

Width

|

3 mm-2600 mm(According to customer requirements)

|

|||

|

Application

|

roofing, ceiling, cladding, gutter, facade wall, etc.

|

|||

|

Surface treatment

|

Mill Finish、Coated、Powder Coated、Anodized、Polished mirror、Embossed、Etc.

|

|||

|

Tolerances

|

As per your requirements

|

|||

|

Delivery time

|

7-30 days after order confirmation

|

|||

|

MOQ

|

1 ton each size or less if we have the same specification in stock.

|

|||

|

Loading Port

|

Qingdao Port, Tianjin Port, Shanghai port.

|

|||

|

Price terms

|

FOB, CIF, CFR, CNF, Etc.

|

|||

|

Payment terms

|

L/C, D/A, D/P, T/T, West Union, Money Gram, Etc.

|

|||

|

Package

|

Seaworthy Wooden pallet, Wooden case, Aluminum plate case

|

|||

|

Factory Service

|

We can provide you with free samples and various custom services.

|

|||

Yongsheng Aluminum Sheet Aluminum Grade

|

1000 Series

|

Industrial Pure Aluminum(1050,1060 ,1070, 1100)

|

|

2000 Series

|

Aluminum-copper alloys(2024(2A12), LY12, LY11, 2A11, 2A14(LD10), 2017, 2A17)

|

|

3000 Series

|

Aluminum-manganese alloys(3A21, 3003, 3103, 3004, 3005, 3105)

|

|

4000 Series

|

Al-Si alloys(4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A)

|

|

5000 Series

|

Al-Mg alloys(5052, 5083, 5754, 5005, 5086,5182)

|

|

6000 Series

|

Aluminum Magnesium Silicon Alloys(6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02)

|

|

7000 Series

|

Aluminum, Zinc, Magnesium and Copper Alloys(7075, 7A04, 7A09, 7A52,

7A05)

|

1100 Aluminum Sheet Physical Properties

| Temper | Thickness (mm) | Tensile Strength (Mpa) | Yield Strength (Mpa) | elongation(%) | hardness(HV) |

| 0 | >0.2-0.5 | 75-105 | ≥25 | ≥18 | 25-30 |

| >0.5-1.0 | ≥30 | ||||

| >1.0-4.0 | ≥35 | ||||

| H22 | >0.2-0.5 | 95-130 | ≥70 | ≥12 | 30-40 |

| >0.5-1.0 | ≥15 | ||||

| >1.0-4.0 | ≥18 | ||||

| H24 | >0.2-0.5 | 110-145 | ≥95 | ≥6 | 38-40 |

| >0.5-1.0 | ≥8 | ||||

| >1.0-4.0 | ≥10 | ||||

| H26 | >0.2-0.5 | 130-165 | ≥115 | ≥2 | 45-60 |

| >0.5-1.0 | ≥4 | ||||

| >1.0-4.0 | ≥6 | ||||

| H18 | >0.2-0.5 | ≥150 | ≥130 | ≥2 | 55-70 |

| >0.5-1.0 | ≥3 | ||||

| >1.0-4.0 | ≥4 |

1100 Aluminum Sheet Packing

Yongsheng aluminum sheet is placed on a wooden pallet or wooden box, wrapped perfectly with waterproof craft paper, and then fixed with a narrow strip of iron.

Usually, we have six layers of packing: put on wooden supports and put desiccant, wrap moisture proof film, wrap the plastic film, wrap the moisture-proof cotton, wrap the plastic moisture proof film again and pack it with cardboard

Aluminum Sheet Packaging Process

The difference Between 1100 and 1060 Aluminum Sheet

1. 1100 aluminum sheet and 1060 are pure aluminum sheet. Aluminum content varies. Generally, the higher the aluminum content, the softer the aluminum sheet is, so the 1100 aluminum sheet is slightly harder than the 1060 aluminum sheet.

1060 aluminum sheet: aluminum content 99.60;

1100 aluminum sheet: aluminum content 99.00.

2. The tensile strength of 1100 aluminum sheet is slightly higher than that of 1060 aluminum sheet. The commonly used thickness tensile strength of 1100 aluminum sheet is 110~136, and the commonly used sheet tensile strength of 1060 aluminum sheet is 95~110.

3. The spot material of 1100 aluminum sheet has many specifications and wide width, and can be flattened into 3 meters, 4 meters, 6 meters, 8 meters, etc.

4. 1100 aluminum sheet is mainly used for curtain wall aluminum veneer, radiator, printing sheet, heat exchanger parts, etc. Can be punched. 1060 aluminum sheet is used for signboards, billboards, building exterior decoration, vehicle body, high-rise buildings and factory wall decoration, kitchen sinks, lamp holders, and other products with low strength.

Both can be bent and welded. Can be used in most cases.

Common Uses of 1100 Aluminum Sheet

1100 aluminum plate is pure industrial aluminum It has the characteristics of small density and good plasticity It is usually used for parts that require good forming performance, high corrosion resistance, and does not require high strength, such as hollow hardware, radiators, welding combinations, reflectors, nameplates, etc.

Uses of 1100 Aluminum Sheet

1100 Aluminum Sheet Characteristics

Low strength aluminum alloy has excellent corrosion resistance and satisfactory anodizing and conversion coating finishing characteristics. It is unmatched by any other commercial aluminum alloy in workability.

Readily to welding, brazing, and soldering. Machinability is poor and tends to be "gummy". Non-heat treatable. Typical applications include chemical storage, processing equipment, kitchen utensils, and general sheet metal work.

As a global supplier of aluminum products, we offer a wide range of solutions to meet the needs of our diverse client base.

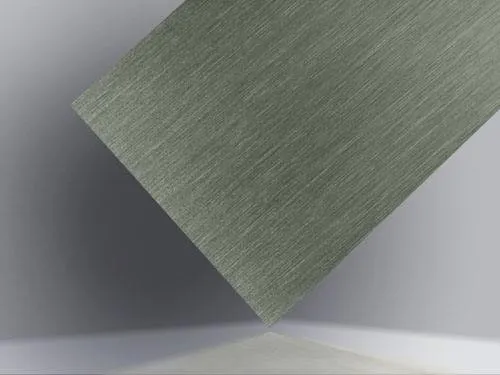

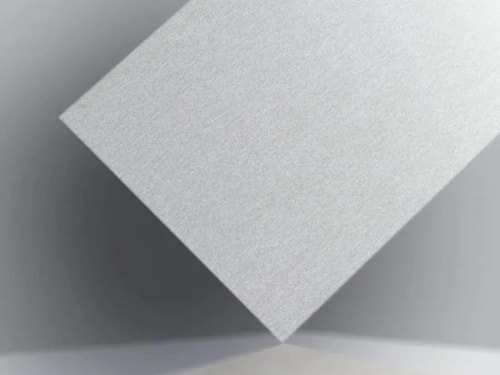

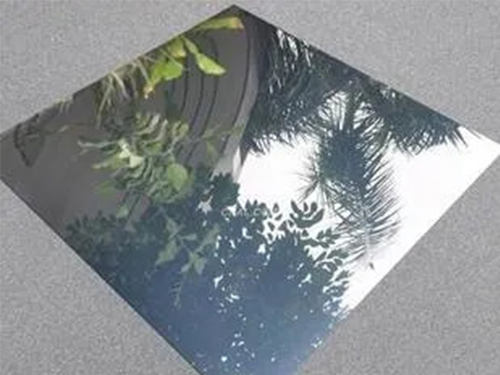

Aluminum Sheet Surface Finish

Anodized, mirror, embossed stucco, etc

Color coated: natural, black, white, blue, red, orange, rose gold, green, golden, etc

Aluminum Sheet Production Process

Smelting —— Ingot casting —— Pre-rolling preparation —— Flat roll rolling —— Heat treatment ——Finishing——Final Inspection——Packing——Delivery

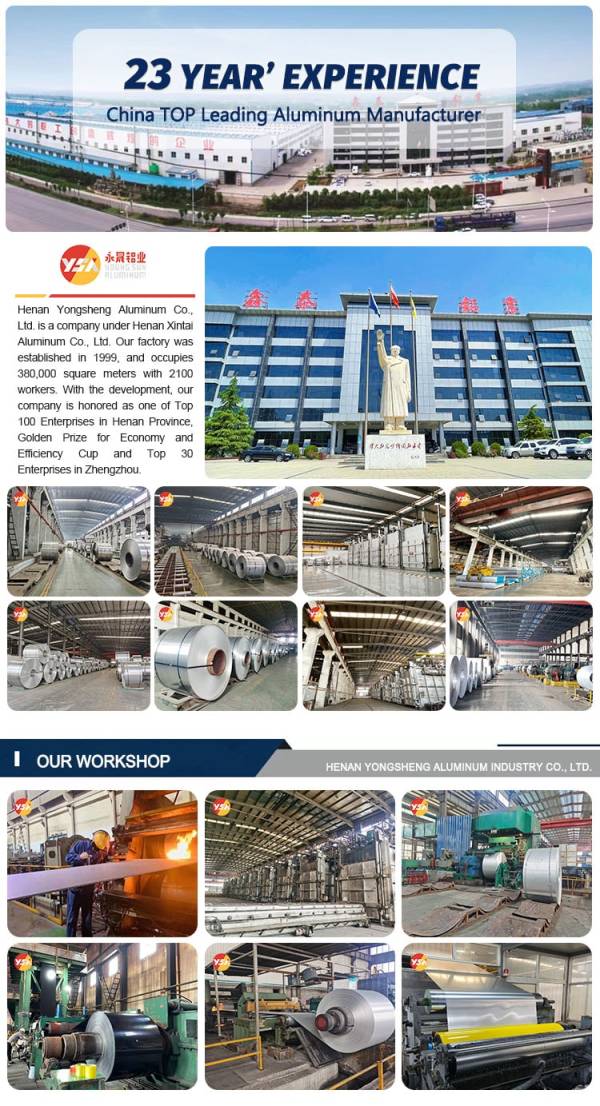

Henan Yongsheng Aluminum Co., Ltd. was established in 1999 and occupies 380,000 square meters with 2100 workers. With the development, our company has been honored as one of Top 100 Enterprises in Henan Province, Golden Prize for Economy and Efficiency Cup and Top 30 Enterprises in Zhengzhou.

We are a Chinese Leading aluminum sheet factory, our main products are as following: Aluminum Sheet/Plate/Coil/Strip/Circle/Foil, Color-coated Aluminum, Aluminum Checker Plate, Mirror Aluminum Sheet and so on. Our capacity is 300,000 MT per year, among which, 35% are exported overseas. At the same time, we supply much famous aluminum companies in China.

Welcome to visit our factory and look forward to establishing a long-term business relationship with you!!!