Diamond tread aluminum, also known as aluminum checker plate or tread plate, is a popular choice for industrial, commercial, and residential applications due to its durability, lightweight design, and eye-catching appearance. However, if you’ve never purchased diamond tread aluminum before, you might be wondering, “What to consider when purchasing diamond tread aluminum?” This piece is here to help! We’ll delve into the crucial factors to consider to guide you through the purchasing process with ease.

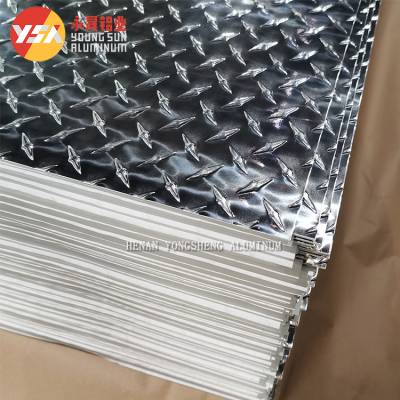

Sizing Matters: Thickness and Dimensions

First and foremost, when purchasing diamond tread aluminum, it’s essential to pay attention to the thickness and dimensions of the sheets. The thickness affects the strength and durability of the aluminum, while the dimensions determine whether the sheets will suit your application. Consider the following factors:

- Thickness: Thicknesses can range from very thin (0.02 inches) to quite thick (0.25 inches). The thicker the sheet, the more load-bearing capacity it has. For high-traffic or heavy-load areas, a thicker sheet may be necessary.

- Dimensions: Diamond tread aluminum sheets come in various widths and lengths to suit different applications. Ensure you measure the space you need to cover accurately so you can order the correct size.

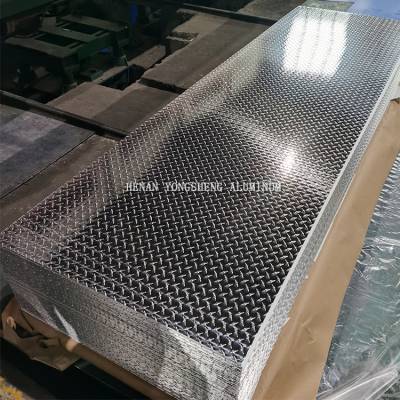

It’s All About the Pattern: Raised and Inverted

When purchasing diamond tread aluminum, the pattern is one of the most important factors to consider. The two primary types of patterns are raised and inverted:

- Raised diamond pattern: This pattern has raised diamond shapes that provide a non-slip surface. It’s the more traditional option and is commonly seen in industrial and commercial settings.

- Inverted diamond pattern: This pattern has inverted, or indented, diamonds, creating a smooth surface that offers less traction but is easier to clean.

Depending on your application, you’ll want to choose the pattern that best meets your needs in terms of safety, function, and aesthetics.

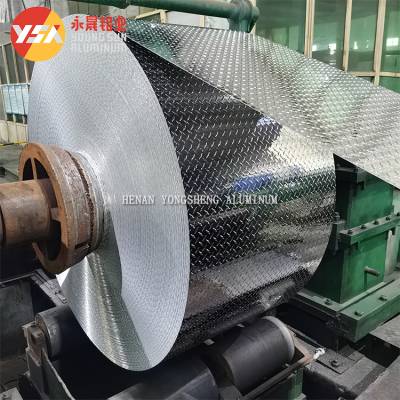

Grading on a Curve: Aluminum Alloy Grade

Not all diamond tread aluminum is created equal – different aluminum alloy grades offer varying levels of strength, durability, and corrosion resistance. Here are a few of the most common grades to consider when purchasing diamond tread aluminum:

- 1100 aluminum checker plate: Pure aluminum with excellent corrosion resistance. However, it has a relatively low strength and is not ideal for heavy-load applications.

- 3003 aluminum checker plate: The most common choice for general-purpose applications, this alloy contains a small amount of manganese for increased strength and corrosion resistance.

- 5052 aluminum checker plate: This marine-grade aluminum boasts excellent corrosion resistance and is used in applications where exposure to saltwater or other harsh environments is expected.

- 6061 aluminum checker plate: With the addition of magnesium and silicon, this alloy is stronger and more resistant to corrosion than the 3003 series. It’s commonly used for heavy-load applications and structural components.

Consider your specific requirements and choose an alloy grade that caters to your needs.

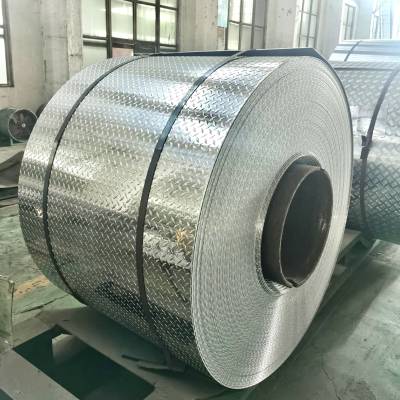

Finish Strong: Surface Finishes

Diamond tread aluminum sheets come in various surface finishes that serve both functional and aesthetic purposes. Some of the most common finishes include:

- Mill finish: A natural, uncoated surface that possesses a uniform, silvery-gray appearance. This finish is suitable if you’re not concerned about maintaining a pristine surface.

- Anodized finish: This finish offers increased corrosion resistance, surface hardness, and a generally smoother surface. It’s available in various colors, allowing for more aesthetic options.

- Powder-coated finish: Perfect for incorporating vibrant colors into your project, powder-coated finishes are applied electrostatically and baked onto the surface to create a strong, durable, and corrosion-resistant coating.

Choose a finish that complements your project’s functional and aesthetic requirements.

A Question of Price: Balancing Cost and Quality

Like with most products, there’s a wide range of pricing when it comes to diamond tread aluminum. While your budget is undoubtedly a significant consideration, it’s vital not to sacrifice quality for the sake of a lower price. Make sure to compare prices from reputable suppliers, considering the factors mentioned above.

FAQs

-

What to consider when purchasing diamond tread aluminum? Consider factors such as thickness, dimensions, pattern type, aluminum alloy grade, surface finish, and price when purchasing diamond tread aluminum.

-

What are the different diamond tread aluminum patterns? The two main patterns are raised diamond pattern (non-slip surface) and inverted diamond pattern (smooth surface).

-

Which aluminum alloy grade should I choose? Your choice of aluminum alloy grade will depend on factors such as strength, corrosion resistance, and application.

-

What surface finishes are available for diamond tread aluminum sheets? Some common surface finishes consist of mill finish, anodized finish, and powder-coated finish.

In Conclusion

Armed with the knowledge of what to consider when purchasing diamond tread aluminum, you can now make a more informed decision. By evaluating factors like thickness, dimensions, pattern type, alloy grade, surface finish, and cost, you’ll find the perfect diamond tread aluminum sheet for your unique application.