What Is Aluminum Strip?

Generally, the raw material of aluminum strip is pure aluminum or aluminum coil cast and rolled with aluminum alloy, hot-rolled aluminum coil, which is rolled into a thin aluminum coil with different thickness and width by cold rolling mill, and then according to its use, after The slitting machine longitudinally cuts aluminum strips of different widths. There are many classifications of aluminum strips. People often use different grades to divide aluminum strips. The common grades of aluminum strips generally include 1050, 1060, 1100, 3003 and 6061 aluminum strips. This article will take the aluminum strip products of Henan Yongsheng Aluminum as an example, and divide the types of aluminum strips in detail, mainly according to the alloy, application, state, surface treatment method, thickness and width of the aluminum strip, to help you understand aluminum in detail belt type.

Aluminum Strip Division

Classified By Alloy

According to the different alloy elements contained in the aluminum strip, the aluminum strip and the aluminum plate are also divided into 8 series. However, the commonly used series are 1000 series, 3000 series, 5000 series, 6000 series and 8000 series.

The 1xxx series aluminum strip is industrial pure aluminum, with good corrosion resistance and formability, and low strength. It is basically used in the chemical tool industry; commonly used alloy grades are 1050 aluminum strip, 1060 aluminum strip, 1100 aluminum strip, etc. 3xxx series aluminum strips belong to aluminum-manganese alloys, have medium strength and good weldability, can be easily formed, and can be used in various industrial applications; the commonly used alloy grade is 3003 aluminum strips. 5xxx aluminum strip belongs to the aluminum-magnesium alloy series, which has a lower density and lighter weight. It is stronger than the 3000 series and maintains good corrosion resistance. It is widely used in aerospace, marine engineering, electronic parts and automobiles; Commonly used alloy grades are 5052 aluminum strip and 5083 aluminum strip. The 6xxx series aluminum strip is an aluminum-magnesium-silicon alloy, which is a cold-processed aluminum forged product. It has good applicability, easy coating, and good processability. It is suitable for applications requiring high corrosion resistance and oxidation resistance; the commonly used aluminum strip grades are 6061. 8xxx series alloys are added with some lithium elements, which not only ensures light weight but also significantly improves strength, has unique properties and is suitable for specific applications; 8011 aluminum strip is the most commonly used aluminum strip in the 8000 series.

Classified By Use

There are many uses of aluminum strips, such as: aluminum-plastic composite pipes, cables, optical cables, bottle caps, fin materials, transformers, radiators, shutters, etc.

For example, 1050 and 1060 aluminum strips are commonly used in transformers, capacitors and transmission lines, as well as radiators, lighting fixtures, kitchen utensils, reflectors and chemical equipment. The 1100 aluminum strip of the same series and the 3003 of the 3 series are used for heat exchangers, air conditioners or refrigerator fins, and evaporator coils. The difference between the two is that 1100 has a price advantage and is used for sheet metal processing, such as roofs and exterior buildings Wall and decorative applications; 3003 aluminum strip is used in some storage tanks, kitchen utensils and general sheet metal processing.

5052 is widely used, such as hulls, fuel tanks and other ship parts, as well as construction, auto parts and general sheet metal manufacturing; 6061 aluminum strips are used for structural components, auto parts and electrical accessories, etc.; 8011 aluminum strips are commonly used in packaging industries, such as bottle caps , closure and lid.

Classified By State

The commonly used states of aluminum strips are O state and H state, which can be followed by some numbers to indicate the hardness and annealing degree. The most commonly used ones should belong to the all-soft series, because the O state is easier to stretch and bend. Specifically, it can be divided into O (full soft), semi-hard (H14, H24, H34), full hard (H18), H16, H26, etc. according to the state.

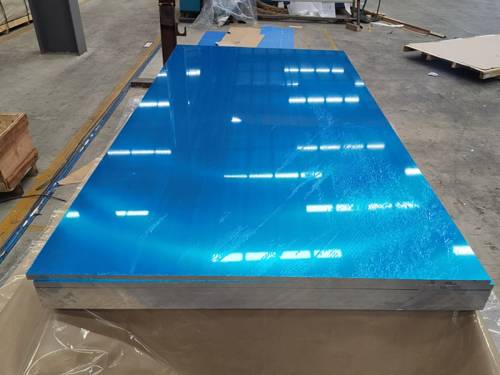

Classified By Surface Treatment

Aluminum strip can be surface treated in a variety of ways, depending on the desired result and specific application requirements. The common surface treatment methods of Yongsheng include anodizing, coating, brushing, polishing, polishing, mirror surface, square and embossing, etc., to ensure the aesthetic effect and meet the personalized customization needs of customers.

Classified By Thickness

Common thickness ranges for aluminum strip vary according to intended use and industry practice. Generally divided according to the following thickness:

Thin strips are typically less than 0.2mm (200 microns) thick; medium-sized strips are typically 0.2mm to 6mm thick; and thick strips are typically 6mm or more thick.

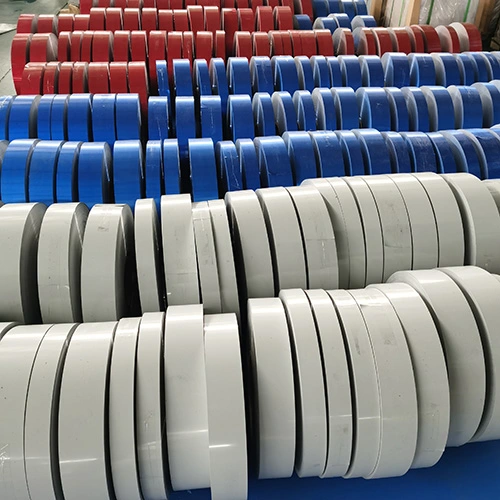

Classified By Width

According to industry standards and specific application requirements, aluminum strip can be divided into different width categories. Narrow aluminum strips are aluminum strips with a width of less than 200mm; medium-sized aluminum strips are generally 200mm to 600mm wide; wide aluminum strips are generally more than 600mm wide.

Summary

Yongsheng Aluminum has advanced technology and can provide pure aluminum strips, transformer aluminum strips, super-hard aluminum strips, fully soft aluminum strips, semi-hard aluminum strips and anti-rust aluminum strips. Whether you are using chemical equipment, containers, parts, lamps, stretched tubes, extruded tubes, or exchangers, sheet metal, hardware products, shutters, etc., as long as you contact us, Yongsheng team will serve you wholeheartedly !